In today’s fast-paced production environment, knowing your manufacturing cycle time — sometimes called production time, turnaround time, or process time — is essential to improving manufacturing performance metrics and production efficiency. Whether you’re optimizing an electronics cycle time, automotive cycle time, or even food production cycle time, tracking this number can make or break your competitive edge.

What Is Manufacturing Cycle Time?

Manufacturing cycle time is the total cycle duration or work time it takes to complete a product from the order release time to the final item ready for shipment. In operations management, it’s one of the most important manufacturing performance metrics because it shows how fast your process turns raw materials into finished goods.

It includes value-added time like setup time and processing time, and contrasts with idle time, which adds no value to the product.

Difference Between Cycle Time and Throughput Time

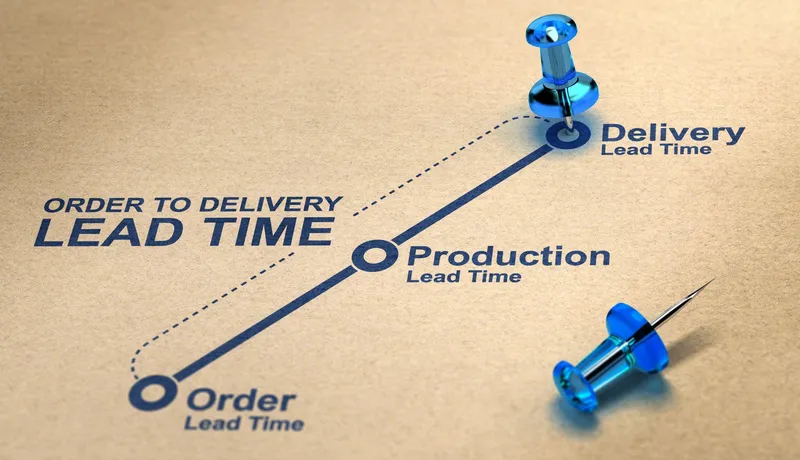

While cycle time focuses on how long it takes to produce one unit, throughput time (or lead time) is the total flow of time from the customer order to delivery. Delay time and downtime are the enemies of both, reducing workflow efficiency and hurting delivery performance.

Why Manufacturing Cycle Time Matters in Modern Production

Reducing your turnaround time and production time directly improves production efficiency, cost management, and supply chain optimization. A shorter cycle means less wasted time, fewer defects, and faster shipping — all of which improve customer satisfaction.

In industries like pharmaceutical manufacturing cycle time or metal fabrication cycle time, the KPI can be the difference between staying profitable or falling behind. Tracking your processing time, inspection time, and wait time as part of your regular manufacturing performance metrics helps identify where efficiency gains can be made.

Manufacturing Cycle Time vs. Takt Time vs. Lead Time

Understanding the differences between these manufacturing performance metrics is crucial for lean manufacturing principles.

What Is Takt Time?

Takt time—sometimes called production rhythm or takt pace—is the speed at which products must be completed to meet customer demand. Unlike cycle time, which can vary, takt time is fixed and calculated based on available production time divided by demand. Too much slack time here means overcapacity; too little means missed orders.

What Is Lead Time?

Lead time (another form of turnaround time) covers the total time from order placement to product delivery. It’s a core part of production planning and control. Excessive delay time or downtime in lead time affects customer satisfaction.

Side-by-side Comparison Table

|

Metric |

Definition | Includes Waiting Time? |

Customer Impact |

|

Cycle Duration |

Time to complete one unit from start to finish | No |

Affects production speed |

|

Takt Time |

Rate needed to meet demand (production rhythm) | No |

Aligns output to demand |

|

Throughput Time |

Total process duration including delay time | Yes |

Impacts delivery times |

|

Lead Time |

Order placement to delivery | Yes |

Directly affects customer |

Types of Cycle Time in a Factory Environment

In production planning and control and industrial engineering concepts, cycle time can be broken into parts: processing time, inspection time, move time, and delay time.

Processing Time

The actual run time, machining time, or operation time when a machine or operator is actively working on a product. This can be machine cycle time or manual cycle time depending on the process.

Inspection Time

Time spent on quality check time or QA duration to verify that products meet standards. Sometimes, automated cycle time for inspections can reduce non-value-added time.

Move Time

The transport time or material handling time needed to move parts between stations. Poor material flow increases wasted time here.

Delay Time

Any wait time, idle time, or buffer time when work isn’t progressing. Reducing this improves flow efficiency and brings you closer to takt-aligned cycle time.

Top Causes of High Cycle Time

Common factors include downtime, idle time, overprocessing, wasted time, and non-value-added time. These issues affect multiple sectors, from metal fabrication cycle time to electronics cycle time, and even food processing cycle time.

Specific contributors:

- Long setup time and lengthy changeover cycle time, often due to inefficient tooling, poor planning, or lack of standardized procedures.

- High rework time caused by recurring quality issues, defective parts, or inadequate quality control systems.

- Excessive wait time between operations because of unbalanced workflows, bottlenecks, or material handling delays.

- Unplanned equipment downtime from maintenance neglect or sudden breakdowns.

- Inefficient communication between production stages, leading to delays in approvals or instructions.

When combined, these factors not only increase total cycle time but also drive up costs, reduce throughput, and impact customer delivery performance.

How to Reduce Manufacturing Cycle Time (Expert Tips)

Improving production efficiency requires addressing each part of the setup time, processing time, inspection time, and changeover cycle time.

Implement Predictive Maintenance

Using manufacturing analytics and operations management tools prevents unplanned downtime and keeps machines in continuous run mode.

Improve Production Scheduling

Better operations management and time management in manufacturing ensures load balancing and streamlines the lead process.

Use Quality Raw Materials

In food & beverage manufacturing, using fresher ingredients shortens the freshness cycle; in textile & apparel manufacturing, better fabrics improve garment cycle time efficiency and reduce rework. This ties directly to cost management.

Train and Empower Operators

Improving manual cycle time through skill development avoids overprocessing and wasted time. Good training ensures consistent operation quality.

Use Cases: How Leading Manufacturers Reduced Cycle Time

Real-world examples show how different industries apply cycle time reduction strategies to improve efficiency, quality, and delivery speed:

- Automotive manufacturing plant applied advanced manufacturing analytics and real-time monitoring to optimize changeover cycle time, reducing overall turnaround time by 15% and minimizing downtime during production shifts.

- Electronics manufacturing company enhanced setup time efficiency and implemented process automation to eliminate rework time, resulting in a 20% boost in throughput and faster product launches.

- Food manufacturing facility streamlined processing time and strengthened inspection time protocols through lean manufacturing practices, cutting total run time by 12% while maintaining strict quality standards.

Final Takeaways

Manufacturing cycle time—also known as production time—is a vital performance metric for boosting production efficiency. By analyzing each stage, from processing and inspection to move and delay time, manufacturers can identify and eliminate inefficiencies. With MettiTech’s advanced manufacturing solutions, companies can apply lean principles and smart cost management to cut turnaround time, enhance product quality, and maintain a competitive edge in today’s fast-paced market.

CONTACT

https://shorturl.fm/7xXgp

https://shorturl.fm/3rx8Q

https://shorturl.fm/l8POn

Interesting points! Seeing platforms like JL3 blend classic gaming with modern tech is smart. Secure account setup-like they detail at jl3 app download-is key for trust. It’s about enjoying the experience and feeling safe while you play.

https://shorturl.fm/YMvY3

https://shorturl.fm/Q5ZQf

Interesting points about bankroll management! Seeing platforms like 365jl login emphasize secure KYC & localized payments (like GCash) builds player trust – crucial for long-term strategy. Solid foundation for analytical play!

That analysis was spot on! Seeing platforms like premyo77 vip really elevate the PH esports scene – smooth logins & easy PHP transactions are a game changer. Great insights on how betting impacts player strategy too! 🔥

Scratch cards always felt like a little burst of optimism, didn’t they? It’s cool to see platforms like ph333 vip prioritizing legal play & responsible gaming-transparency is key! Plus, easy deposit options are a win. 😊

https://shorturl.fm/lgfkW